|

|

|

| |

Pharma Accessories, Butterfly Valves, Sterile Coupling, Powder Sampling |

|

| |

|

|

| |

| |

| |

We are Manufacturer, Supplier, Exporter of Pharma Accessories, Butterfly Valves, Sterile Coupling, Powder Samplings from Pune, Maharashtra, India.

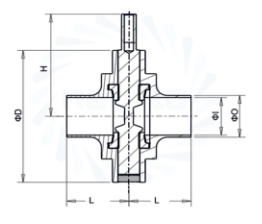

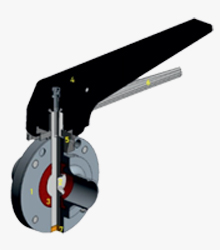

| Neuflo hygienic butterfly valves are distinctly compact designed and manufactured to perform reliably in difficult production environments assuring complete safety. Neuflo valves are meticulously made in India, using the finest raw materials available. These valves feature specially designed integrated mounting holes for bracketing to precision align optional pneumatic actuators. All valve bodies are precision CNC machined from high quality stainless steel and feature an I.D. finish of less than 0.6mm Ra. Allen bolts on the body are cross threaded which ensure a tight sealing, withstanding the process fluid line vibrations. |

Features - |

|

• Designed as per cGMP norms, Hygienic. |

|

• Available in SMS/ISO/BS/3-A/DIN. |

• Optional end connections(weld/male/clamp). |

• One-piece disc and stem assembly. |

• Fully machined 304L/316L stainless steel body. |

• Bi-directional capability. |

• Fully hygienic design with auto option. |

• Isolation or regulation control. |

• High flow coefficient(Cv). |

• Various food grade seat material options. |

• Multi position handle assembly. |

|

| |

| |

| |

Technical Specifications - |

|

• Multi position handle assembly.

• Valve Body - forged 304L / 316L stainless steel, CNC precision machined finish- Ra<0.6�m.

• Disc-forged 316L CNC machined 12x8 mm capsule headed stem, Mirror Polish Finish- Ra<0.4�m.

• Gasket Seats - Silicone, EPDM, FKM, PTFE ( FDA approved elastomers ).

• Handle - High impact Nylon / SS 12 position gripper handle with in built SS insert.

• SS Notch plate

• SS Grip Lever

• Elastomer Tail Bush

|

|

|

ISO range weld end butterfly valves

|

| Size |

ɸ I |

ɸ0 |

L |

ɸD |

H |

| DN25 |

22.6 |

25 |

34 |

79 |

61 |

| DN38 |

35.6 |

38 |

38 |

86 |

64.8 |

| DN51 |

48.6 |

51 |

40 |

105 |

74.3 |

| DN63.5 |

60.3 |

63.5 |

40 |

112 |

77.6 |

| DN 76.1 |

72.9 |

76.1 |

41 |

125 |

84.8 |

| DN101.6 |

97.6 |

101.6 |

44 |

157 |

101.7 |

|

| |

|

|

|

| |

|

|

|

| |

| |

|

|

| |

|

| |

|

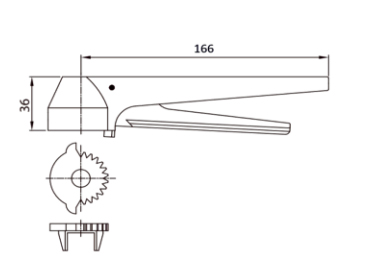

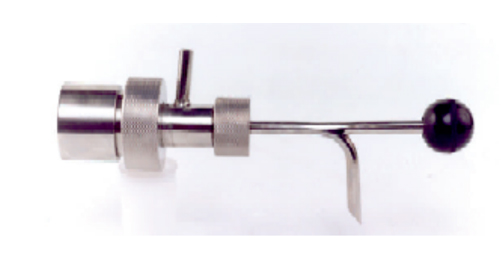

SMB X-FLOW POWDER Sampling Valve

|

| |

|

SMB X_Flow powder sampling valves are designed to extract powder/granular forms of samples from tanks, reactors or piplines in a complete hygienic way that is non clogging and cleanable

Seals: |

|

� Available in silicon,EPDM.

Features:

• Lockable inline sampling system that is,collection scoop of valve can be turned 180 degrees in one direction.

• Full T-grip handle easy to use allows good grip.

• It can be cleaned easily and assembled again.

• No dead space,completely cleanable detachable design

Technical Specifications:

• Model :SMB-X flow

• Mounting : 50.8mm OD TC end.

• MOC : SS316L

• Operation : Manually by handle 180 deg turn to open / close

• Inlet Powder Scoop Volume :6 cm3

• Oulet connection :25.4 mm TC end

• Plunger Dia. and Length : Dia 35.7mm( Length 67.5mm in open position & 134 mm in close)

• Max Operating Temp : 160 Deg C

• Working Pressure : 6 Bar(g)

• Internal Surface Finish : 0.4 Ra electropolished

• External Finish : Satin/Glossy

• Cleaning : Manual by removing plunger after change of product

Material of construction:

The contact part are of SS316L grade and the clamps are of SS304.seals are of silicon.

Options :

sampling bottles and extended stroke length

|

|

|

|

Working :

SMB X-Flow sampling valve provides inline sampling of free flowing and non free flowing materials (granules,powders,flakes,powdered milk and pharmaceutical products in gravity chutes and hoppers. Scoop provided can be pushed inside and can be pulled outside with sample then turned 180 degree using the handle to take the sample in a bottle/ flask

Valve Size :1", 1.5", 2", 2.5", 3" weld end,weld thickness 2mm.

Powder Size : 10 micron to 1/4"(6mm) particle size.

Quantity of Sample :upto 10grams.

Temperature Range : upto 80 deg cel.

|

| |

|

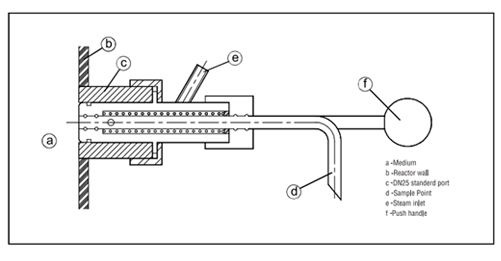

STERI SAMPLE VALVE MODEL KT-02

|

|

|

|

Sampling from tanks and pipeline under sterile conditions for physico-chemical or micro biological Analysis

Valve Body : Stainless steel AISI 316L (welding parts with material certificate)

Sealing : Silicone EPDM in request

Product Pressure : Max.4bar (65PSI) as standard 6 bar is available on request.

The valve body is available in following executions :

• Type 'F' for direct welding into tanks / flange

• Type 'P' for direct welding into pipe / fermented

The manually actuated steri sample valve are steam sterilisable and designed to suit hygienic norms

Sampling should only be made from sterile sample valve.Before opening the valve,closing cap should be placed on sample piece. There after handle is moved on horizontal position until required flow through lowe outlet is obtained.After sampling, handle should be left as it is automatically in this position the handle can not be removed.

Cleaning / Sterilisation :

After sampling the valve should be flushed with water or alcohol. Sterilisation is to be done by alcohol or steam.when not in use, the valve may be sealed with alcohol by leaving the clip-onclosing cap on the lower outlet and filling with alcohol.By aseptic sampling the channel is to be rinsed with alcohol.

Cleaning in place only with vessel or pipeline cleaning by interval flipping or valve optimal cleaning of valve seat is obtained

|

| Technical Data : |

Max operating temperature |

: |

150 �C |

|

|

|

CMax.operating pressure |

: |

6bar |

|

|

|

Material-parts in contact with medium |

: |

316l |

-o-ring |

: |

EPDM |

| Details For Ordering |

Sapmling valve Dn25 |

: |

20101 |

|

|

|

with steam diaphragm valve

|

: |

20102 |

|

|

|

with sterile cartridge |

: |

20103 |

with stem diaphragm valve and sterile cartridge |

: |

20104

|

| |

|

|

| Mounting : On tanks and pipe workNormally the valve should be mounted horizon-tally with one outlet in upward position and onein downward. If the valve is mounted in anotherposition if should be seared that complete drain-age can take place from one of the outlets. |

|

| |

|

| |

|

| |

spare Part list : Part No |

Oprating information(example) |

| Sterilisable in place with alcohol or steam |

2001 :0'rings |

Model :Type P-KT-01 |

Representative sampling, giving repeatable results |

2002 :SS 316 springs |

Application : Fermented broth |

Safe tosecondary contamination |

2003 :SS316L fixing Nut |

Size: DN25 |

Dual purpose, bulk and micro samples (special version) |

2004 : 25mm DN port nut |

Type of mounting Socket |

Manual and User-Friendly |

2005 8mm OD sampling tune |

|

|

| |

|

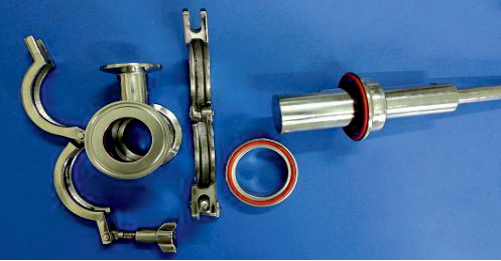

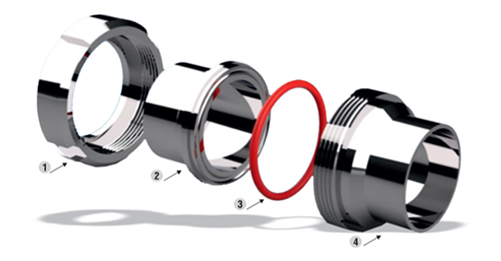

STERILE UNIONS BIOPHARMA APPLICATIONS DN 25.4 to DN 76mm

|

Features:

• Sceptic fittings for Biopharma Industries

• OC SS316L and O Ring Food grade silicon

• Temp Max 180 Deg C, Pressure 10 Bar(g)

• Internal finish 0.4 Ra, Electropolished

• External Finish Mirror Polished / Satin

Features:

• Sterile unions nut

• Sterile unions liner

• Silicon food grade o-ring

• Threaded liner

|

|

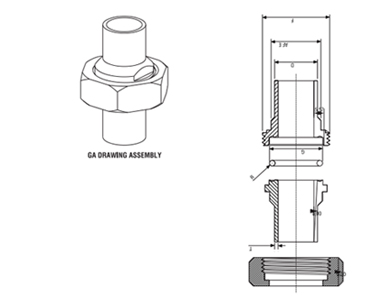

| STERULE UNION SMB-SU-03- GA Drawing & Dimensions |

| Sr.No |

Model Name |

A |

B |

C |

D |

E |

F |

R |

T |

| 1 |

DN 63.5 |

17 |

27 |

29.4 |

75 |

63.5 |

68 |

1.5 |

2.1 |

| 2 |

DN 76 |

20.1 |

33.3 |

30 |

87.4 |

76 |

78 |

1.5 |

2 |

ALL DIMENSIONS ARE IN MM

|

|

| |

|

|

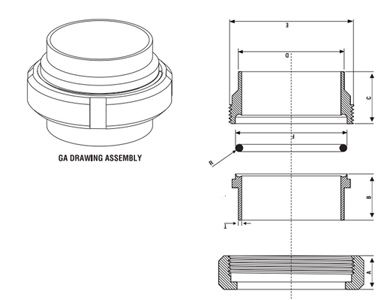

STERULE UNION SMB-SU-01- GA Drawing & Dimensions |

|

| Sr.No |

Model Name |

A |

B |

C |

D |

E |

F |

G |

RT |

| 1 |

DN 8 |

12.1 |

27.4 |

28.1 |

8 |

17 |

21.8 |

15 |

1.41.6 |

| 2 |

DN 12.7 |

12.1 |

27 |

28 |

12.7 |

17 |

21.8 |

15 |

1.251.6 |

| 3 |

DN 19 |

12.6 |

27.3 |

28.6 |

19 |

22 |

29.75 |

23.5 |

1.251.6 |

|

|

| |

|

| |

|

|

| |

| |

|

|

| |

|

|

| |

|

|

|

|

|

|

|